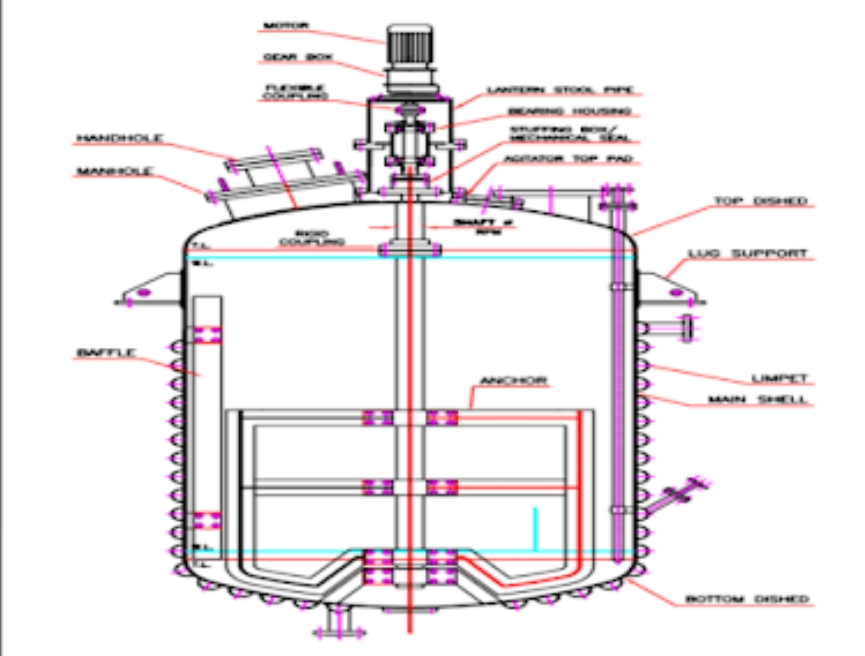

Chemical Equipment and its main Parts uses and Maintenance operation

Definition of Kettle/ Reactor: –

A Kettle is an enclosed volume in which a chemical reaction takes place.

MOC of Kettle:

SS

MS

MSGL

HDPE

FRSVE

Herten

Body of Kettle

It is mainly hemispherical dish end cylinder with limpet or jacket around it.

Accessories on Kettle

Motor

Gear Box

Lantle assembly

Mechanical seal/Gland filling

Thermo well

Level transmitter

Agitator

Baffles

Flush bottom valve

Dip pipe or Diverter

1.Motor

It is use for driving Agitator in Kettle as it converts electrical energy to mechanical.

Mainly Motor of All kettle is Having 1440 RPM, but some time as per requirement we use 2900 RPM motor

Depend on Zone of classification we use FLP or Non FLP motor.

Some motor shaft has gear mounted and some having pulley.

2.Gear Box

Mainly use for reducing speed of agitator from speed of motor.

Gear ratio is depend on application and process requirement.

• Maintenance

• Check for any oil leakage

• Top up oil if level got lowered.

• Check foundation bolts

• Check belt condition is applicable

3.Lantle Assembly

It is mainly for holding shaft at centre of the kettle and give bearing in it for shaft in bearing housing in it.

Maintenance

- Do greasing to bearings in bearing housing.

- Check bearing housing bolt condition and its tightness.

- Check condition of coupling bolts and its tightness.

4.Mechanical seal

It uses for avoiding fumes from reactor inside to come out from reactor.

It also helps for keeping shaft concentric and avoid run out of shaft.

Types of agitator seal

- Single dry mechanical seal

- Double mechanical seal

Chemical Equipment and its main Parts uses and Maintenance operation

also read:- automobile engineering interview questions

Dry mechanical Seal

5.Thermo well

• It is for measuring temperature of chemical inside the kettle

• cylindrical fittings used to protect temperature sensors installed in industrial processes

• Typically, a thermowell is made from metal bar stock

• A thermowell acts as a barrier between a process medium and the sensing element of a temperature measuring device.

• Silicon oil is use for enhancing heat transfer from process fluid to RTD rod

6.Level transmitter

• This instrument is for level indication inside kettle

• It may be mass or radar type

Chemical Equipment and its main Parts uses and Maintenance operation

Agitator

An agitator is a mechanical device that helps in shaking or stirring a liquid or mixture of liquids. Agitators are widely used for multiple operations in the chemical, pharmaceutical, food, grease, metal extraction, paint, adhesive, water, and cosmetic industries

To get proper mixing of liquids.

To promote chemical reaction inside the equipment.

To increase heat transfer during heating or cooling

To keep homogeneous liquid bulk during storage.

To disperse immiscible liquids.

To keep the product in a mixed state till used.

Types of Agitators :

Turbine Agitators.

Paddle Agitators.

Anchor Agitators.

Propeller Agitators.

Helical Agitators.

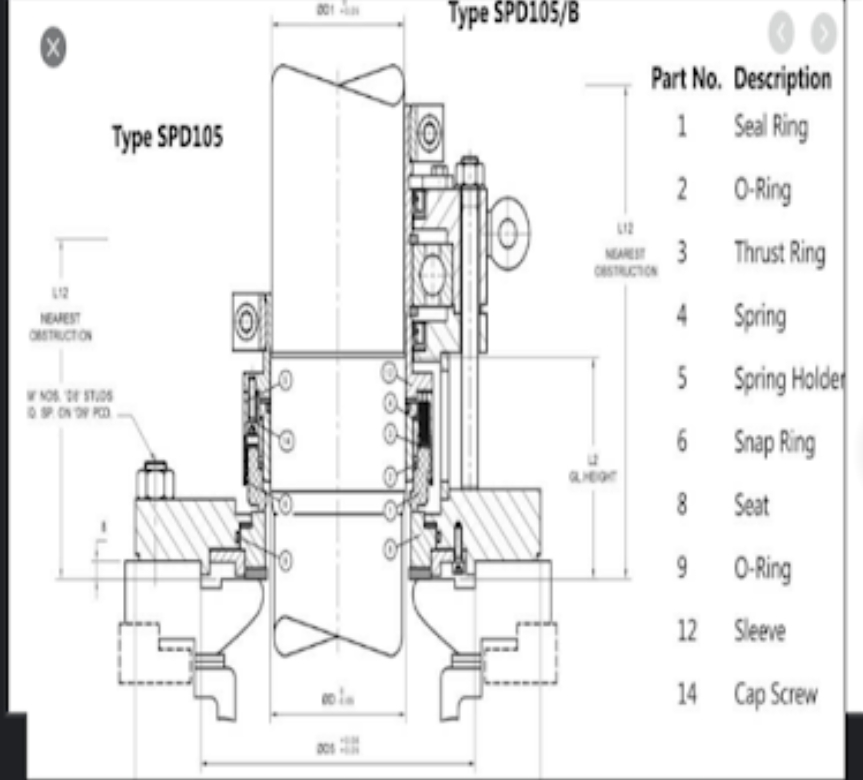

Mechanical Seal Balanced – Unbalanced seal for Vessel/Reactor and Pump – Maintenancemech

What is the use of Mechanical Seal (m seal)?

Mechanical Seal -Mechanical seals are devices that are used to provide a seal at the point of entry or exit of a rotating shaft.

it is used to prevent the leakage of one high pressure fluid into a lower pressure fluid.

Earlier we used Gland packing instead of mech seal, but due to gland rope is wear and leak again and again then m seal invention for presentation of any leakage.

Mech seal has two faces, one face is fixed with housing which is called stationery seal and other one face is rotating face seal which is rotates with shaft.

Seal Component

Rotating primary face – Fixed to and rotates with the shaft and seals against the stationary primary sealing element

Stationary primary face – Fixed to the stationary housing of the pump, mixer or other equipment through which the rotating shaft passes and seals against the rotating primary sealing element

Mechanical loading devices – Biases the primary sealing elements in contact to initiate sealing. These can be a single spring, multiple springs, wave springs, or metal bellows.

Static and/or dynamic secondary seals – Seal between the mechanical seal components and the equipment shaft and housing that compensates for any shaft movement that may damage the seal faces.

Drive mechanisms – Set screws and drive pins are examples of drive mechanisms used to provide rotation to the rotating primary seal face.

Material of mech seal

Carbide, silicon, tungsten, carbon and Teflon PTFE, SS

Note – PTFE is used for acid.

Types of Mechanical Seal –

Balanced seals.

Unbalanced seals.

Pusher seals.

Non-pusher seals.

Conventional seals.

Cartridge seals.

Balanced seals –

Chemical Equipment and its main Parts uses and Maintenance operation

Balanced seals reduce the seal ring area (Ah) on which the hydraulic pressure of the liquid in the pump (Pp) acts. By reducing the area, the net closing force is reduced. This allows for better lubrication that results in lower heat generation, face wear, and power consumption.

In the balanced seal, the opening area or face area is same as the unbalanced seal, but the closing area is maintained in proportion to the face area.

Chemical Equipment and its main Parts uses and Maintenance operation

The pressure from both the seal springs (Ps) and the hydraulic pressure of the liquid in the pump (Pp) provide a compression force that keeps the seal faces closed. Balanced seals reduce the seal ring area (Ah) on which the hydraulic pressure of the liquid in the pump (Pp) acts.

Balanced seal is use for more than 10kg/cm^2 pressure is maintaining.

Un balanced Mechanical Seal –

All mechanical seals are available in balanced and unbalanced versions.

Unbalanced seal generates multiple times higher hydraulic closing force generated by the actual pressure that seals the two faces.

Though they are more stable than the balanced ones, if the closing force on the seal faces crosses the pressure limits, then it wears out the lubricating film which squeezes out, and the dry seal fails due to heavy load.

Un balance pump is used for less pressure which is below 10kg/cm^2.

Compare between Balanced and Un balanced Seal –

Heat Generation

More in unbalanced seals

Less in balanced seals

Seal life

More in balanced seals

Less in unbalanced seals

Vibration and stability

More stable and aligned

Less stable and misaligned

Liquid handling capacity

Unbalanced seals can handle high capacities of high lubricity fluids

Balanced seals can handle high capacities of poor lubricity fluids. They are best fit for light hydrocarbons

Seal face loading

High in unbalanced

Low in Balanced

Heat Generation

Heat generation across the face is more in unbalanced seals

Heat generation across the surface is low in balanced seals

Mechanical seal for Agitator In vessel /Reactor –

Agitator or Reactor Mechanical Seals are specifically designed for Mixer, Agitator and Reactor applications, to combat the inevitably radial and / or axial shaft movement that occurs in these applications.

Single Mechanical Seal

Double Mechanical Seal

Dry Mechanical Seal and

Glass line reactor Seal

Chemical Equipment and its main Parts uses and Maintenance operation

Single Mechanical Seal

Operating Range –

• Shaft Día: 25mm to 150mm

• Temperature: -30degree Celsius to 200 degree Celsius

• Speed: 400rpm

• Pressure: Full Vacuum to 30 bar

Material

Seal Ring Face – Carbon and silicon

Seat Face TC and sic

Elastomer Viton, TTV and FEP

MOC- SS316.

Chemical Equipment and its main Parts uses and Maintenance operation

One Comment on “Chemical Equipment and its main Parts uses and Maintenance operation”